Replacing a Fender USA Stratocaster Bi-Flex Truss Rod Nut

For some reason known only to Fender, the US American Standard Stratocasters and Telecasters use a 1/8″ Allen key to adjust the Bi-Flex truss rod. It’s okay if the rod is working well and whoever adjusts it used a tight-fitting key of the correct size, but if not, the nut can quickly be trashed and require replacement.

Replacing the nut is not difficult but does, like every job, require a bit of care. It sits behind a walnut plug which has to be removed. The nut pushes against this plug if you use the truss rod to introduce bow into a neck.

The first step is to score the finish around the plug so that it isn’t damaged. I omitted to photograph this step.

Next the glue that holds the plug in has to be softened. I did this by placing the bit of a soldering iron into the hole. This required more heat than I expected and did cause a little charring of the plug but this is being replaced with a new one. No pictures here either sorry!

Once the glue is soft, turning the truss rod nut anticlockwise will cause it to act against the plug and push it out.

Once it’s far enough out to grip, pliers can be used to pull it all the way out.

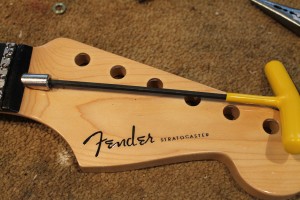

The nut can now be withdrawn using the 1/8″ Allen key.

Once the nut is out it’s important to clean the sides of the hole so that the new plug will fit and the glue will adhere to the sides.

Here are the old and new nuts so you can see how chewed the hex socket was.

The new nut should be inserted and nipped up. I applied a smear of lithium grease to the threads and inner face before I refitted it.

I roughly shaped the new plug on my belt sander and tested it for fit.

Next job is to put the small washer back in and glue in the plug with a little Titebond.

Once the glue is dry the plug can be carefully sanded flush…

…then refinished to match the surrounding headstock.

The only thing left to do was to set the guitar up with the user’s chosen 9-42 strings. I think it’s the first time in a long while that the neck on this guitar was been straight!

Hi, I’m curious on opinions of adding a washer as a spacer if the truss rod is bottomed out… meaning I can’t tighten the truss rod anymore before reaching the end of the threads.

I think this was how my nut got stripped prior to me buying it. I replaced it after purchase

Yes it’s common to add a washer (or more than one) to a truss rod in order to give a bit more adjustment.

Hi. What does the phrase “nipped up” mean? I’m about to fit a plug an not sure how much the new nut should be threaded on to the truss rod. Thanks!

It means “just tight”

They used to, though. From 1982 to 1984 and from 1989 to 1995, U.S.-made Fender basses did have Bi-Flex truss rods. But since basses rarely need counterclockwise truss rod adjustment, more powerful single-action truss rods with a larger diameter replaced Bi-Flex truss rods in Fender basses.

I know this is an older post. Looking for some advice. I just did this repair a few months ago. Nut was badly stripped when I bought the neck. Now I can’t seem to get the neck as straight as I would like, even with the rod very tight.. Did you put any back bow in the neck before replacing the plug? I feel like maybe that’s what needed to be done in my case. When I read Fenders explanation of the biflex rid, it apparently uses the plug as part of the mechanism. I have an extra plug if I need to repeat the process.

The truss rod nut acts against the plug to give back bow so you can’t introduce any before the plug is fitted.

The problem is probably in the neck or rod and the nut was stripped trying to straighten the neck when it’s just not possible. Sorry.

All very good but it all falls apart if the trussrod nut cannot be used to push out the plug. My method is basically the same as yours but prior to heating the plug I tap in a 1/4″ thread. once the glue is melted I quickly run a 1/4 rod into the plug and yank it out. Once the plug is removed the nut can be accessed but that is another issue all together.

Thanks for the tutorial. What kind of finishing clear did you used for the plug?

Thank you for showing how to do it :)

I need this to be done on my strat …

A quick point, if the hex socket is badly chewed up and you can’t get a hex wrench to grip try using a Torx bit, it will grip where the hex doesn’t (it’s also possible to gently tap in an oversize Torx bit into the damaged hex socket)

What type of stain did you finish the plug with?

I didn’t use any stain, that’s the natural colour of the walnut.

What finish do you use ? Thanks

This is excellent! Thanks. Where did you get the plugs?

I think I bought a pack of two on eBay but a Fender dealer or AllParts should be able to get them.

OK, thanks, Steve. I’ll try that.

Excellent instruction and pictures.

would this work on any other kind of biflex rod. EG I have a ‘Vintage’ (JHS brand) guitar and the thread has stripped on the nut. Could I remove the plug and chgange thenut in the same way.

Cheers mart

“Biflex” is a Fender trademark and no other make of guitar uses this kind of truss rod (thankfully).

The two-way truss rod in your Vintage is a totally different construction and the nut isn’t removable.

Thanks for this info Steve, that’s very helpful.

All the best

martin